Study on combustion characteristics of high flame retardant metal composite panel curtain wall system in different standard fire test

Study on combustion characteristics of high flame retardant metal composite panel curtain wall system in different standard fire test

Liao jianbo Zhu huaguo Chengjia Wang xiaohong

(Hunan KEOCT Materials Co., Ltd, Hunan Plastics Research Institute Co., Ltd. Changsha ,Hunan ,410100)

Abstract :This paper conducts an experimental research on the combustion characteristics of high-flame retardant metal composite fire-retardant panels in the fire-proof test of three large/medium-scale curtain wall systems of BS8414, NFPA285 and GB/T29416, in order to provide a reference for the selection and application of fire-resistant curtain wall materials for high-rise buildings.

Keywords :high-flame retardant metal composite fire-retardant panel ; Building curtain wall system; Fire performance test

preface

On November 9, 2021, the Fire Rescue Bureau of the Ministry of Emergency Management released the national fire situation report from January to October this year. In the first 10 months of this year, over 70% of fatal fires occurred in residential areas, with 15 major fires occurring in densely populated areas, accounting for 22.1% of the total. Restaurants, shopping malls, cinemas, and other densely populated areas are more prone to major fires that result in mass casualties. Therefore, it is urgent to use high-efficiency flame-retardant materials.

In the past, flame retardancy often only required materials not to be easily ignited by small fire sources, but now it is not only required that materials not be easily ignited by small fire sources

Ignite, and also require materials or components to have the lowest possible heat release rate, while requiring low smoke production and low smoke toxicity. When a fire occurs, different materials usually burn to varying degrees, and there are various factors that affect the combustion of materials, such as the location of the ignition source, the strength of the fire source, ventilation conditions, and the shape of the material. In such a complex system, it is difficult to accurately and objectively measure all parameters of the material's combustion performance. In this situation, fire test methods for large/medium-sized curtain wall systems have emerged, and the most representative fire tests for curtain wall systems include American standard NFPA285, British standard BS8414, and national standard GB/T29416. We used high flame retardant polyethylene as the core material and prepared high flame retardant metal composite panels using continuous extrusion thermal composite technology. The insulation material used was rock wool. We conducted fire tests on the three types of curtain wall systems mentioned above.

1. Selection of experimental materials

We use KEOCT High Flame Retardant and Fireproof Polyethylene as the core material, double-sided 0.5mm thick metal plate, and 0.05mm thick polymer adhesive film. We use a two roll continuous thermal composite production process to prepare a 4.0mm thick high flame retardant metal composite board. The insulation material is rock wool and corresponding fire partitions are set up. Installation tests are carried out according to the above three system fire test standards. The main performance indicators of the high flame retardant metal composite board used are shown in Table 1.

Tab 1 Main performance index of high-flame retardant metal composite fire-retardant panel

|

Serial number |

Project |

Company |

Inspection basis |

Inspection results |

|

one |

Density (core material) |

g/cm3 |

GB/T3033-2008 |

1.70±0.05 |

|

two |

Hot 3 (core material) |

MJ/kg |

GB/T34402 |

9.3±0.02 |

|

three |

Surface density |

Kg/m2 |

GB/T27748-2016 |

7.9±0.03 |

|

four |

bending strength |

MPa |

126 |

|

|

five |

Flexural modulus of elasticity |

MPa |

3.6x104 |

|

|

six |

Penetration resistance |

KN |

9.0 |

|

|

seven |

shear strength |

MPa |

32.0 |

|

|

eight |

Drum peeling strength |

N.mm/mm |

GB/T2447 |

Average 4:166 Minimum 4:143 |

2. NFPA285 Medium Proportion Multi layer Structure Fire Protection System Test

2.1 Comparison of HFR-ACP NFPA285 before and after the experiment using KEOCT flame-retardant and fire-resistant polyethylene as the core material. Figure 1:

|

|

|

|

Before the test |

during the test |

after the test |

Fig1 the photos during the test

2.2 NFPA285 test results

The test results of using the above-mentioned high flame retardant metal composite board in NFPA285 medium proportion multi-layer structure fire protection system are shown in Table 2:

Tab 2 NFPA285 test results

|

Serial number |

Experimental parameters |

Technical indicators |

experimental result |

|

one |

Is there a fire in the two rooms above the window sill |

no |

no |

|

two |

What is the temperature at 2.5 meters and 5 meters above the edge of the fire window Does it exceed 537.7 ℃. |

<537.7 ℃ |

462.3 ℃ |

|

three |

Flame longitudinal and transverse propagation length/m |

<Longitudinal and transverse limits |

<Longitudinal and transverse limits |

|

four |

Did it cause extensive burning on the exterior wall? |

no |

no |

2.3 Experimental analysis

According to NFPA 285 experiment, flames on external fire-resistant metal composite panels are within the set limits; The flame did not spread to the core components or infiltrate into the second floor room; The thermocouple did not exceed the maximum limit. The metal composite board made of halogen-free high flame retardant polyethylene core material underwent a 40 minute ignition and combustion test, and the flame did not spread extensively along the metal composite board from the window, only a small part was burned off, indicating good flame retardant effect.

3. Fire performance test of external wall insulation system BS 8414-1:2015A+2017

3.1 Comparison of Experimental Processes in BS 8414-1:2015A+2017

During the experiment, photos were taken to compare the experimental phenomena after 3 minutes, 8 minutes, and 13 minutes, as shown in Figure 2

|

|

|

|

3 minutes after ignition |

8 minutes after ignition |

13 minutes after ignition |

Fig2 the photos during the test

3.2 Peak value of temperature curve

3.2.1 Peak values of temperature curve, as shown in Table 3

|

Parameters |

result |

|

Start temperature |

26.2°C |

|

start time |

2 minutes and 52 seconds after ignition |

|

Horizontal baseline 2 external peak temperature/time |

517.3 °C (16 minutes and 35 seconds after ignition) |

|

Peak temperature/time of internal cavity of horizontal baseline 2 |

171.6 °C (17 minutes and 50 seconds after ignition) |

Table 3 Peak temperature curve

3.3 Test Results

This experiment was conducted in accordance with BS8414-1:2015+A1:2017, with a testing time of 60 minutes. The test results are shown in Table 4 below:

Tab 4 BS8414-1 test results

|

Standard |

result |

|

|

Testing time (minutes) |

Conclusion |

|

|

External fire spreading |

≥ 15 minutes |

adopt |

|

Internal fire spreading (depth of cavity) |

≥ 15 minutes |

adopt |

|

Internal fire spread (at medium depth of separation system) |

≥ 15 minutes |

adopt |

|

Visible flames: During the entire 60 minute testing period, it is required that there be no visible flames exceeding the vertical or horizontal limits. Visible flames are defined as continuous flames with a duration exceeding 60 seconds (i.e. uninterrupted or non luminous). |

60 minutes |

adopt |

|

Mechanical properties: During the entire 60 minute testing period, it is required that the system or component does not collapse (with a length of at least 500 millimeters and a weight of 200 grams), and whether there is a fire or no fire on the floor of the testing facility outside the designated collapse area. |

60 minutes |

adopt |

|

Burning droplets: During the entire 60 minute testing period, the collapse area of the testing facility outside the designated location is required to have no burning droplets |

60 minutes |

adopt |

|

Note 1: The collapse zone is defined as 2.4m x 1.2m, located at the center of the centerline of the combustion chamber opening (with a length of 2.4m parallel to the combustion chamber surface). |

||

4. GB/T29416-2012 Fire Performance Test for Exterior Wall Insulation System of Buildings

4.1 GB/T29416-2012 Test Overview

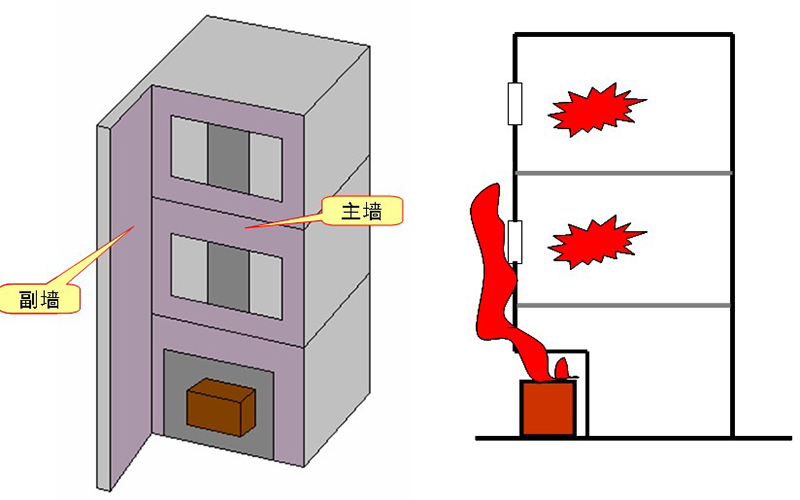

GB/T29416-2012 refers to BS8414-1:2002 "Fire resistance performance of building cladding systems - Part 1: Test methods applicable to non load bearing cladding systems on building surfaces". Based on the development of building fire, it mainly simulates the flame and hot smoke emitted from windows after a fire occurs in a building room, spreading upwards along the wall and producing thermal effects on the external insulation system of the building curtain wall, causing further decomposition and combustion of the external insulation material, and the flame spreading upwards, as shown in Figure 3.

Fig3

4.2 Test Results

The results of the fire resistance test of the high flame retardant fire-resistant metal composite board in GB/T29416-2012 building exterior wall external insulation system are shown in Table 5:

Tab 5 GB/T29416-2012 test results

|

Serial number |

Experimental parameters |

Technical indicators |

experimental result |

|

one |

Continuous visible flames |

During the entire experimental period, the specimen experienced combustion and the visible flame continued to be less than 9m in height in the vertical direction, or less than 2.6m along the main wall or 1.5m along the auxiliary wall outside the angle between the main wall and the auxiliary wall in the horizontal direction. |

Less than the specified value |

|

two |

External flame spread |

Horizontal baseline 2: The external thermocouple temperature is less than the initial temperature of 600 ℃ for a duration of less than 30 seconds |

536℃ |

|

three |

Internal flame spread |

The internal thermocouple temperature of horizontal baseline 2 is less than the initial temperature of 500 ℃ for a duration of less than 30 seconds |

469℃ |

|

four |

The flame spreads in the collapsed area |

The falling object exceeds the collapse area or continues to burn within the collapse area for less than 3 minutes. |

Not exceeding, continuous combustion for less than 3 minutes |

|

five |

Smoldering |

Vertical direction: not exceeding the horizontal reference line 2 Horizontal direction: The distance between horizontal reference lines 1 and 2 does not exceed the outer boundary of the secondary wall |

Not exceeding |

|

six |

system stability |

The collapsed object does not exceed the collapsed area |

Not exceeding |

5. Experimental conclusion

5.1 The firepro of metal composite board made of halogen-free high flame retardant polyethylene core material, according to NFPA285 test, after 40 minutes of ignition and combustion, the flame did not spread widely along the firepro of metal composite board from the window, only a small part was burned, and the flame retardant effect was good.

5.2 The curtain wall external cladding system using high flame retardant metal composite fireproof board shall be tested in accordance with the British standard BS8414 Part 1:2015+A1:2017 "Test Method for Fire Performance of Building External Cladding Systems". The highest temperature measured outside the horizontal reference line 2 is 517.3 ℃, and the highest temperature measured inside is 171.6 ℃; And in this experiment, it can be seen that the flame, mechanical properties, and combustion droplets inside and outside the collapse area all meet the specified requirements.

5.3 The high flame retardant fire-resistant metal composite panel adopts GB/T29416-2012 building exterior wall external insulation system fire test, and the relevant indicators meet the test requirements.

5.4 GB/T29416-2012 Test Methods for Fire Performance of Exterior Wall Insulation Systems for Buildings and BS 8414-1:2015A+2017 Test Methods for Fire Performance of Exterior Wall Insulation Systems are similar but not equivalent, and all three test methods mentioned above have similarities.

5.5. Through the above experiments, it can be concluded that the test of the curtain wall external cladding system is closely related to the fire resistance performance and installation method of the curtain wall decoration materials and cavity insulation materials, and all three are indispensable; The fire-resistant metal composite board produced using the flame-retardant polyethylene core material of KEOCT can be tested through the above three test methods.

reference

[1] WANG X H,LIAOJ B,ZHU H G,et al.Latest research progress and market application of on-line extrusion fire-resistant metal composite panels and their halogen-free high flame-retardant core[J] Chin Building Mater Sci Technol,2018(11):76-79.

[2] WANG X H, ZHAO C G.Flame retardant fire security testing and materials application research for APCP[J].China Plast Ind,2012(1):55-60.

EN

EN

中文

中文

阿拉伯

阿拉伯