"The 20th anniversary of the establishment of the China Building Materials Metal Composite Branch" celebration album article -- creating the preferred brand of KEOCT flame retardant core material

Hunan KEOCT Materials Co., Ltd. is a national high-tech enterprise specializing in the research and development, production, and sales of environmentally friendly flame-retardant modified new materials. It is a subsidiary of Hunan Haili, an A-share (600731) listed company, and was founded by Hunan Plastics Research Institute and scientific and technological personnel in 2003. It is located in the national level Changsha Economic and Technological Development Zone. The company is committed to innovating and promoting environmentally friendly materials such as "green, low-carbon, fire safety", and working together to create a better life for humanity.

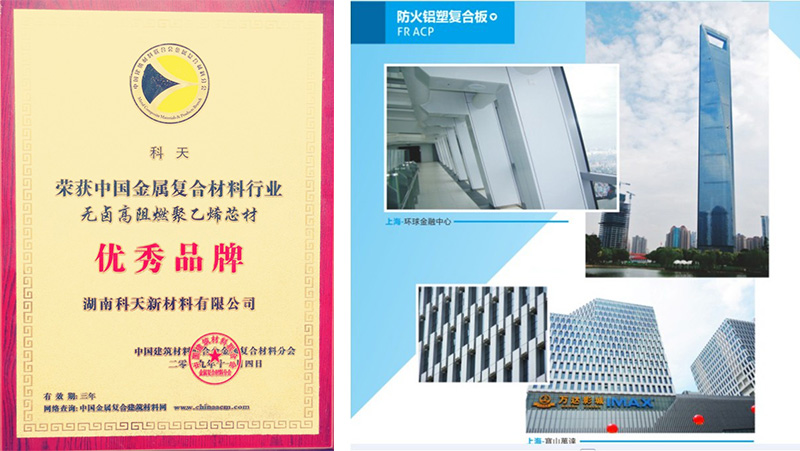

The company has 19 national patents (including 3 authorized invention patents) and is the drafting unit for two national standards GB/T 17748 and GB/T22412, as well as one industry standard JC/T 2561. The company's core product - halogen-free flame-retardant polyethylene core material for metal composite materials, in addition to leading technological advantages, also maintains stable quality and is easy to process and shape, making it the preferred brand for customers in the Chinese metal composite materials industry. Has won honors such as National Key New Product, China Light Industry Federation Science and Technology Award, Hunan Provincial Science and Technology Progress Award, and Independent Innovation Energy saving and Environmental Protection Products.

The company is the Vice Chairman Unit of the Metal Composite Materials Industry of China Construction Association and one of the top ten suppliers in the Chinese metal composite materials industry. The China aluminum-plastic composite building materials industry flame retardant technology research and development center, Hunan Province Key Laboratory of Polymer Materials Application Technology flame retardant technology center, and fully biodegradable materials industry university research base are all located in our company.

The company's core products have passed domestic and international authoritative testing and certification such as the National Building Materials Testing Center, the National Fire resistant Building Materials Quality Supervision and Inspection Center, SGS, INTERTEK, TUV PSB, etc. The fire-resistant metal composite panels of different types (copper, steel, aluminum, titanium zinc, etc.) produced by our company using high flame retardant core materials have been tested for their combustion performance according to domestic and foreign building material fire prevention standards such as GB8624 in China, ASTM E84 \ E119/NFPA285 in the United States, DIN4102-1 in Germany, EN13501-1 in the European Union, BS476-6/7 in the United Kingdom, BS8414-1 in Russia, GOST30244-1, ISO5660-1, SASO 2571, etc. At the same time, their physical and mechanical properties meet the technical requirements of GB/T17748 "Aluminum plastic Composite Panels for Building Curtain Walls". The company's products have passed ISO 9001:2015 international quality system certification and implemented 24-hour online quality monitoring. Widely used as a new type of decorative material for indoor and outdoor building curtain walls, it has also been extended to fields such as smart appliances, subway and high-speed rail.

1、 The development history of KEOCT:

1. The largest shareholder of the company, Hunan Plastic Research Institute, is one of the five major plastic research institutes in China that was established in 1965 to develop modified polymer materials. It won the National Science and Technology Conference Award for the first time in 1978 and was successfully restructured in 2000; In 2017, the company underwent a corporate restructuring and entered Hunan Haili High tech Industrial Group. In 2022, it was acquired by Hunan Haili Chemical, a A-share listed company;

2. The company is the first domestically developed flame-retardant polyethylene core material for B1 grade fireproof aluminum-plastic panels. In 2001, it was awarded the "National Key New Product" trial production plan project, and in 2005, its product formula and manufacturing technology were granted one national invention patent authorization for the first time;

3. The company's series of halogen-free high flame retardant material formula technology and preparation methods have obtained a total of 19 national patents (including 3 authorized invention patents);

4. The industrialization research and development of new halogen-free flame-retardant polyethylene functional materials has passed the appraisal of scientific and technological achievements in Hunan Province, and the establishment of the "Hunan Province Key Laboratory of Polymer Material Application Technology - Flame retardant Material Research and Development Center" has been carried out; Received the Excellent Award for Scientific and Technological Progress in China's Light Industry in 2007;

5. From 2008 to 2020, it was awarded the title of "National High tech Enterprise" for the fifth consecutive time, with an annual export of up to 5 million US dollars;

6. The company's project won the Hunan Provincial Science and Technology Progress Award in 2008 and became one of the first high-tech enterprises; In 2009, the project was supported by the Small and Medium sized Enterprise Innovation Fund of the Ministry of Science and Technology; The "KEOCT" trademark has been awarded as a famous trademark in Hunan Province;

7. The establishment of the "China aluminum-plastic composite building materials industry flame retardant technology research and development center" in our company in 2012 is a recognition from the industry; And take the lead in advocating industry associations to jointly initiate and write an emergency appeal letter with relevant enterprises regarding Article

6.7.7 of the "Code for Fire Protection Design of Buildings" (draft for approval), which has been recognized;

8. In 2013, the first phase of the industrial production base for 12000 tons of halogen-free flame-retardant new materials was expanded; Starting from 2020, we have successfully expanded the second phase of a large-scale production base with an annual output of 26000 tons of environmentally friendly modified new materials and biodegradable products.

9. The formal promulgation and implementation of two national standards, including GB/T17748, which participated in the formulation and revision in 2016; In 2020, we plan to build a new research and development production base and become a leading enterprise in the field of technology innovation and entrepreneurship in the subdivision of halogen-free flame retardant new materials.

Looking back at the arduous process of innovation and entrepreneurship over the past 20 years, KEOCT Company set sail in 2003 to carry out the transformation of industry university research achievements, taking the lead in applying halogen-free flame retardant technology innovation and industrialization to China's metal composite panel materials industry, achieving import substitution and filling the domestic gap.

Against the backdrop of increasing attention to environmental protection and safety both domestically and internationally, KEOCT's products are currently exported to over 20 countries and regions including Russia, Southeast Asia, the Middle East, Europe, and North America. Wang Xiaohong, the founder of the company and a professor level senior engineer, also won the honors of "exemplary individual in China's Light Industry", "Top Ten Figures in the Metal Composite Industry of the China Construction Federation", and "Leading Talents in Science and Technology Innovation and Entrepreneurship in Changsha City".

Accompanied by honor and mission, KEOCT will forge ahead, ride the wind and waves, and achieve new successes!

2、 The core competitiveness of KEOCT

1. The company was founded on April 8, 2003, and is a national high-tech enterprise established by scientific and technological personnel from Hunan Plastic Research Institute, the earliest and most professional plastic new material research and development institution in China.

2. The earliest specialized company in China to develop and produce flame-retardant polyethylene for fireproof aluminum-plastic panels, with the largest production and sales volume.

3. Comrade Wang Xiaohong, the chief expert of halogen-free flame retardant technology in the company, was the only person who was awarded the title of "Outstanding Contribution or Top Ten Figures in China's aluminum-plastic composite panel industry" by the industry association in 2006, 2012, and 2017. Led by him, the Sci Tech Innovation and Entrepreneurship Team is committed to promoting the continuous development of fire-resistant metal composite panel technology and industry upgrading, and expanding the promotion and application of aluminum-plastic composite panels at home and abroad.

4. The preferred supplier of high flame retardant core materials for top domestic and foreign industry brands (including all Chinese famous brands of aluminum-plastic panels), and the preferred brand enterprise with the highest export volume of halogen-free flame retardant core materials in the country.

5. The fire-resistant aluminum-plastic panels developed and produced meet the standards of GB8624 B-S1, d0, t0 in China, GOST30244 G1 in Russia, ASTM E84 Grade A in the United States, Grade 0 and 1 in BS476-6/7 in the United Kingdom, DIN4102-1 Grade B1 in Germany, EN13501 B-S1, d0 in the European Union, etc., which can meet the fire prevention standards and specifications for building materials at home and abroad.

6. The earliest and only flame-retardant material supplier in China to pass the 2-hour fire resistance limit test of ASTM E119 standard and NFPA285 medium-sized building window fire test in the United States.

7. The only flame-retardant material supplier in the industry whose daily quality testing of halogen-free flame-retardant products is conducted by a nationally recognized laboratory - Hunan Province Plastic Product Quality Supervision and Inspection Authorization Station, with 24-hour monitoring throughout the entire process.

8. The historical accumulation of the only excellent brand of high flame retardant polyethylene core material in the industry in 2019 and the famous trademark in Hunan Province in 2009 has created the preferred brand of high flame retardant core material for fire-resistant aluminum-plastic panels with the highest engineering application inspection standards and usage height in the past 20 years at home and abroad.

3、 How can China's metal composite materials industry better achieve high-quality development in the future?

We believe that fire-resistant metal composite panel material is a new type of high-end wall decoration material for fire safety and cleaning. It is a new high-end decorative material for modern curtain walls, interior decoration, and ceiling decoration. It is mainly used in public places such as airports, stations, subways, sports venues, shopping malls, office buildings, high-end cultural and entertainment centers, gas stations, etc. Its product characteristics and market applications will achieve high-quality development with the technological progress and continuous innovation of the industry!

1. The supply chain and process equipment technology of fire-resistant metal composite board materials have basically matured at home and abroad, and their application is scientific and reasonable, in line with the development direction of safety, environmental protection, green, low-carbon and energy-saving industry policies in various countries.

High flame retardant fire-resistant aluminum-plastic panels such as Mitsubishi, Aruk Bang, and Renault from the United States are widely promoted as B-class fire-resistant aluminum-plastic panels. They have not actively promoted the so-called A2 grade fire-resistant aluminum composite panels because many testing methods abroad are relatively complete and scientific. Efficient fire-resistant B-class fire-resistant panels can fully meet the needs of building curtain wall decoration and are energy-saving, low-carbon, and environmentally friendly. Compared to single metal materials such as aluminum veneer, aluminum honeycomb panel, and three-dimensional panel, it saves resources and reduces costs.

2. Industry associations in the new era and enterprises on the new journey should continue to stay true to their original aspirations, uphold integrity and innovate.

① Industry associations and related enterprises must conscientiously study and implement the spirit of the 20th National Congress of the Communist Party of China, remain true to their original intentions, uphold integrity and innovation, unite as one, strengthen communication and coordination, and promote the work of relevant national departments to create a good industry environment and market atmosphere;

② Continue to strengthen the joint research and development of upstream and downstream industries, as well as the innovation of key core technologies. Metal composite panel factories, equipment manufacturers, and high flame retardant core material product development and production units should continue to jointly overcome technical difficulties in their respective production equipment, processes, and supply chain safety, in order to promote the technological progress and product upgrading of the entire industry's fireproof aluminum-plastic panel; Fuel suppliers should strive to continuously improve their material formulations, supply chain safety, and toughness according to the requirements of different customers and the different standards of various countries. This will enhance the overall cost-effectiveness and decorative functionality of metal composite panels, continuously reduce production and manufacturing costs, and provide support for the safe and high-quality development of the entire industry.

③ Strengthen the promotion, application development, and engineering supervision of fire-resistant metal composite board materials in the industry. The application and promotion of fireproof board products aims to enter the high-end markets at home and abroad, and successfully develop high flame retardant fireproof aluminum-plastic panels through online composite extrusion. Although high flame retardant and fire-resistant aluminum-plastic panels are currently used in small quantities in the domestic market, they have achieved large-scale mass production and sales in foreign countries due to the strong promotion of Mitsubishi and Aruk Bang, becoming their main sales product and secret weapon for occupying the market. They are generally used in places with particularly strict fire protection requirements. This technical difficulty has gradually been overcome domestically, and it is believed that it will form a large-scale production application during the 14th Five Year Plan period.

④ Correctly understand the classification testing methods and standards for the combustion performance of building materials, and effectively respond to the technical indicators requirements of the "Code for Fire Protection Design of Buildings" and the new national standard GB/T17748-2016. With the revision of GB50016 "Code for Fire Protection Design of Buildings" and the introduction of the new national standard GB/T17748-2016, aluminum-plastic panel enterprises should strengthen the research and development of high flame retardant extruded core materials for the production of fire-resistant aluminum-plastic panels and stability testing of typical fire protection standards in developed countries. New products that can stably meet the combustion performance of the new national standard should be mass-produced as soon as possible. The fire safety characteristics and drum peeling strength of the materials should be comprehensively examined, and the one-sided pursuit of A1 or A2 level judgment should not be blindly pursued; It should be discussed whether the maximum values of flame spread, surface damage, combustion time, maximum temperature, and other parameters meet the latest domestic and international standards "Test Method for Fire Performance of Building External Wall Insulation Systems".

⑤ The combination system of high flame retardant and fire-resistant metal composite panels and A-grade insulation materials is feasible and highly promising for use in high-rise buildings with three or more floors. According to the evaluation results of relevant curtain wall fire prevention tests conducted both domestically and internationally, as well as the requirements of the latest fire prevention standard 6.7.8, the combination of high flame retardant fireproof aluminum-plastic panels and A-level insulation materials can mostly meet the standards of the "Test Method for Fire Performance of Building External Wall External Insulation Systems" and relevant fire safety design requirements for building curtain walls, and can be applied to building curtain wall decoration.

Policies such as the 14th Five Year Plan and the "dual carbon" strategy have a positive driving effect on industry technology in the future Hunan KEOCT Materials Co., Ltd will focus more on internationally leading environmentally friendly functional new material technology, seize new development opportunities, continuously improve core competitiveness, increase research and development investment and global market expansion efforts, and create an excellent KEOCT brand.

We firmly believe that with the promotion and application of fire-resistant metal composite board materials at home and abroad, the demand in the market should continue to gradually increase. We must not forget our original intention, forge ahead, seize opportunities, lead the market, continue to increase research and development investment, and strive to continuously improve and innovate the halogen-free high flame retardant series of specialized core materials, contributing to the healthy development of China's building materials industry metal composite board new materials industry!

We will continue to uphold the corporate spirit of "innovation, hard work, unity, and efficiency" and the business philosophy of "products are like character", never forget our original intention, forge ahead, work together with industry colleagues, uphold integrity and innovation, and jointly write a new era of high-quality and common development for Hunan KEOCT Materials Co., Ltd and the industry!

Twenty years of spring and autumn changes have witnessed the glorious history of China's aluminum-plastic composite materials industry!

After twenty years of hard work, we have reaped fruitful results in the Chinese metal composite materials industry!

EN

EN

中文

中文

阿拉伯

阿拉伯